- Plate Heat Exchanger

- Gasketed Heat Exchanger

- Welded Heat Exchanger

- Brazed Heat Exchanger

- Spiral Heat Exchanger

- Plate and Shell Heat Exchanger

- Plate Evaporator and Plate Condenser

- Sub-station System for District Heating and Cooling

- Maintainance Spare Parts

- Dezionised Water Cooling Unit For Medium-Voltage AC Drive System

- Contact Us

-

China Office

3F, Bld 1 Luzhou Zhonghuan Business Center 1628 Jinshajiang Rd Shanghai 200333

Email sales@plateheatingexchanger.com

Description of Plate Heat Exchanger System

Accessen's ABJ Series plate heat exchanger system (plate heat exchanger unit) has good environment protection performance. The operation noise is lower than 70dB, with compact structure, good exterior and reliable performance. The capacity of unit is from 350 kW to 1500kW, capable for supplying heating for above 400,000 square meters, and five class control methods which could be optional to end user.

The plate heat exchanger system is a system which integrated plate heat exchanger, water treatment, circulating pump, supplement pump, thermal meter, pressure meter, various of sensors, pipeline, valves and control unit. The whole system is designed into five sub-systems, water supplement system, pressure setting system, frequency conversion flow system, thermal meter and network communicative control system. With advantage technology, rich experience, standard module design, high stand parts supporting, we supply complete and humanized solution in system, you just make server connection, then we can handle who system running at your site.

Application of Plate Heat Exchanger System

Heating: Thermal Station for district heating

Hot Water: Domestic hot water supply system and process water cooling system

Sub-station System for District Heating and Cooling

Textile and Papermaking: Heating Recycle from exhaust and waste water

Chemical Engineering: Heating and cooling process during chemical reaction

Air Conditioning: Chilling water heat exchanger device for central air-conditioning system of large scale building

Food Industry: Pasteurization for milk, beer, beverage and soy

Machinery: Lubricant and hydraulic oil cooling and emulsion cooling

Metallurgy: Blast furnace cooling system, continuous casting cooling system and oxygen generator cooling system

Technical Parameters of Plate Heat Exchanger System

ABJ, PS Series ABJ-SA010-600 II 1.0 & PS-WA-1

Connection Size: DN20 - DN500

Max Flow Rare: 1200m3/h

Max Load: 50MW

LMTD: 1.0℃

Thickness: 0.5、0.6mm

Max Pressure: 25Bar

Material of Gasket: NBR、EPDM、HNBR

Material of Plates: AISI304, 316, 316L, Titanium

Typical Application: HVAC, Process Heating & Cooling, Hot Water

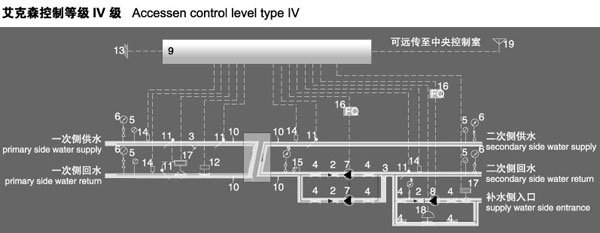

Case Illustration

Equipments list for above case

| Item NO. | Equipment Name |

| 1 | Plate Heat Exchanger |

| 2 | Ball Valve |

| 3 | Filter |

| 4 | Butterfly Valve |

| 5 | Thermometer |

| 6 | Pressure Meter |

| 7 | Circulation Pump |

| 8 | Supplement Pump |

| 9 | Control Cabinet |

| 10 | Blow-down Valve |

| 11 | Temperature Sensor |

| 12 | Electrical Regulation Valve |

| 13 | Outdoor Temperature Sensor |

| 14 | Pressure Sensor |

| 15 | Safety Valve |

| 16 | Frenquency Converter |

| 17 | Flow Meter |

| 18 | Electronmagnetic Valve |

| 19 | Wireless Modem and Antenna |

Accessen International LLC is a plate heat exchanger system (plate heat exchanger unit) manufacturer, designer, distributor and servicer in China. The heat exchangers are widely used in the HVAC, cooling, power, metallurgy, chemical, food, electronics, marine, and environmental industries. Our products have been exported to Asia, the Middle East, and Eastern Europe, such as Russia, Ukraine, Poland, Indonesia, Thailand, UAE, Qatar, Saudi Arabia, Pakistan, Bangladesh, Mongolia, India, Iran, Jordan, Venezuela, Macedonia, Singapore and Vietnam. If you need plate heat exchanger system, please don't hesitate to contact us.

-

- Gasketed Heat Exchanger

1. AU, AC, AS, AP Series

2. Connection Size: DN32-DN500

3. Max Flow Rare: 4500m3/h

4. Max Load: 60MW

5. Temperature Approach: ...

-

- Welded Heat Exchanger

1. Laser welding for plate, no gasket.

2. High hear transfer efficiency with almost all plate surface for heat exchanging.

3. Low cost of using and maintenance

English

English Português

Português Русский

Русский